In recent years, the automotive industry has witnessed one of the most remarkable transformations in its history.

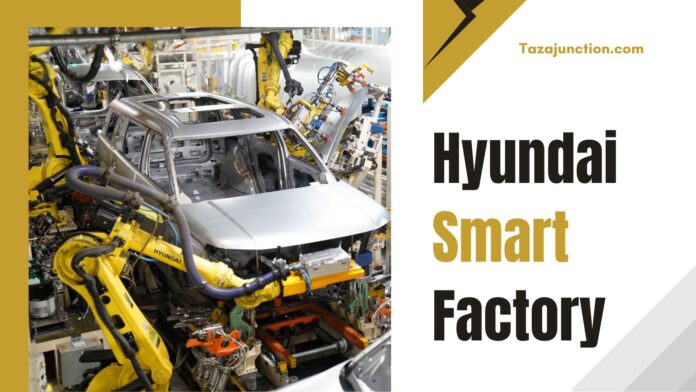

At the center of this revolution is the Hyundai smart factory, a groundbreaking approach to manufacturing that blends artificial intelligence (AI), electric vehicle (EV) innovation, automation, and sustainable practices.

By embracing digitalization, Hyundai aims not only to redefine how cars are made but also to set new benchmarks for efficiency, safety, and environmental responsibility.

This TazaJunction.com article takes you deep inside the Hyundai smart factory, exploring its innovative technologies, its role in shaping EV production, and the wider implications for the future of global manufacturing.

Table of Contents

The Vision Behind Hyundai’s Smart Factory

The concept of the Hyundai smart factory is rooted in the idea of Industry 4.0, where AI, robotics, big data, and machine learning drive production systems. Unlike traditional car plants, Hyundai’s new-age facility is designed to be fully digital, flexible, and sustainable.

The company envisions a future where cars are not just products but part of a connected mobility ecosystem. To achieve this, the Hyundai smart factory integrates predictive analytics, autonomous robots, and cloud-based systems to optimize every stage of production.

This vision is also tied to Hyundai’s long-term commitment to carbon neutrality, where clean manufacturing processes and renewable energy play a central role.

Role of AI in Revolutionizing Production

Artificial intelligence lies at the heart of the Hyundai smart factory. From quality control to predictive maintenance, AI ensures that the entire system operates smoothly and efficiently.

For instance, AI-powered sensors continuously monitor equipment and predict potential breakdowns before they occur. This predictive maintenance reduces downtime, saves costs, and improves safety.

Moreover, AI-driven quality checks detect even the smallest anomalies in car parts, ensuring that customers receive vehicles with unmatched reliability.

The Hyundai smart factory also uses AI algorithms to plan workflows, adjusting them dynamically depending on production needs, parts availability, and worker schedules.

EVs Take Center Stage

One of the primary reasons Hyundai invested heavily in its smart factory is the rise of electric vehicles. The global demand for EVs has surged, and manufacturing them requires a completely different setup compared to internal combustion engine cars.

The Hyundai smart factory is specifically optimized for EV production. Automated guided vehicles (AGVs) transport heavy batteries safely across the plant, while robotic arms assemble components with precision. AI ensures that every battery pack undergoes rigorous quality checks before being integrated into the vehicle.

In addition, the facility is designed to adapt quickly to changing EV technologies. As battery chemistry and designs evolve, the factory’s modular system allows production lines to be reconfigured without long downtimes.

Human and Machine Collaboration

While automation and AI play dominant roles, the Hyundai smart factory doesn’t eliminate the need for human workers. Instead, it creates a collaborative environment where people and machines work together.

Workers are equipped with wearable devices that provide real-time instructions, safety alerts, and performance metrics. Collaborative robots, or “cobots,” assist humans in repetitive and physically demanding tasks, reducing fatigue and workplace injuries.

This human-machine synergy is one of the key factors that sets the Hyundai smart factory apart from traditional car plants.

Sustainability at the Core

Sustainability is another pillar of the Hyundai smart factory. The facility incorporates renewable energy sources like solar panels and wind power to reduce its carbon footprint.

Smart energy management systems monitor electricity usage in real time and automatically adjust operations to minimize waste. Water recycling systems and eco-friendly materials further ensure that the factory aligns with Hyundai’s global commitment to green manufacturing.

By embedding sustainability into its operations, the Hyundai smart factory sets a precedent for how future manufacturing hubs should operate in an environmentally conscious world.

Data as the New Fuel

Data is the lifeblood of the Hyundai smart factory. Every machine, robot, and process is connected through the Industrial Internet of Things (IIoT), creating a constant stream of information.

This data is analyzed in real time to make immediate adjustments. For example, if a machine detects a deviation in assembly, AI algorithms can instantly correct the process. Over time, this wealth of data builds predictive models that continuously improve efficiency.

By using big data and cloud computing, the Hyundai smart factory ensures scalability, meaning the lessons learned in one plant can be instantly shared with others around the globe.

The Global Impact of Hyundai Smart Factory

The innovations seen inside the Hyundai smart factory have far-reaching implications beyond the automotive industry. By pioneering a model of AI-driven, sustainable, and flexible production, Hyundai sets new global benchmarks.

Competitors in the automotive space are already taking note. The facility demonstrates that digitalization and sustainability can go hand in hand, providing a blueprint for other manufacturers to follow.

Moreover, the Hyundai smart factory shows how advanced technologies can boost economic growth, create high-tech jobs, and contribute to national strategies for industrial modernization.

Challenges Ahead

Despite its success, the Hyundai smart factory faces challenges. Cybersecurity risks are high in a fully connected environment, and protecting sensitive data is crucial.

Additionally, the integration of human workers with advanced machines requires extensive training and reskilling programs. Balancing automation with job creation remains a delicate task.

Finally, as EV demand continues to grow, the Hyundai smart factory must constantly innovate to stay ahead of evolving battery technologies and global competition.

The Future of Manufacturing

The story of the Hyundai smart factory is more than just a corporate success—it’s a glimpse into the future of manufacturing. Factories of tomorrow will rely on AI, automation, and sustainability to deliver products faster, cleaner, and smarter.

As Hyundai continues to refine its model, the automotive industry will likely see more companies adopting similar strategies. This evolution will not only reshape how cars are built but also redefine the very nature of industrial production.

Conclusion

The Hyundai smart factory represents a bold step forward in the journey toward Industry 4.0. By blending AI, EV-focused systems, automation, and sustainability, Hyundai has created a manufacturing hub that reflects the future of mobility.

From predictive maintenance and quality control to renewable energy and human-machine collaboration, every aspect of the factory embodies innovation.

While challenges remain, the Hyundai smart factory sets a powerful example for industries worldwide, showing how technology and sustainability can coexist to drive progress. In essence, Hyundai is not just building cars—it is building the future.